Trusted By Marine Industry Professionals For More Than 6 Decades.

Duramax Marine® has a unique depth of marine experience that no other company offers. For decades, we have been there for the marine industry with the right answers to solve tough maintenance problems.

Marine professionals depend on our experience, continuing research and advancements in product technology.

Duramax Marine is a long- time, dedicated member of the marine industry. Our products are engineered to increase vessel performance to meet the demands of an ever-changing industry. When customers compare our quality standards to the competition, they can appreciate the difference. Our commitment to excellence is evident in our product performance records, and our unmatched service customers depend on. It's how we've earned the trust of the marine industry.DURAMAX MARINE® QUALITY POLICY

DURAMAX MARINE®, in providing products and services to our Customers, is committed to comply with and satisfy applicable requirements. We are dedicated to constant improvements in every area of our business and to doing our job right the first time so as to achieve total customer satisfaction.A History of Duramax Marine Product Achievements.

Water-Lubricated Bearing Systems

We invested millions of dollars in research and development to understand the tribological intereactions of water lubricated bearings. We use this knowledge to engineer rubber formulations that allow our bearings, still today, to set performance records other bearing materials are still trying to reach.

We invested millions of dollars in research and development to understand the tribological intereactions of water lubricated bearings. We use this knowledge to engineer rubber formulations that allow our bearings, still today, to set performance records other bearing materials are still trying to reach.

It's why more than 90% U.S. Navy surface ships and submarines operate with Duramax water-lubricated bearing technology.

Johnson Cutless Bearings

Duramax Johnson Cutless Bearings are the first, only true Cutless Bearings. They are used in more vessels around the world than any other water lubricated bearing, because of their unmatched performance in the harshest of working environments. Many have tried to copy our Johnson Cutless Bearing, but none have the knowledge to produce our proprietary rubber formulations or quality of manufacturing. As of today, no other water lubricated bearing material matches the performance record of our Johnson Cutless Rubber Bearing.

Johnson Demountable Stave Bearings

Heavy Nitrile rubber staves that can be installed easily without removing the shaft or propeller, drastically reducing maintenance time and cost. It's a custom-fitted bearing that improves shaft alignment, and reduces vibration that can cause excessive wear and shaft damage.

ROMOR I Bearings

One of our most advanced bearing materials. Specially-formulated, molded rubber 80-durometer Shore A stave bearing with a glass-smooth facing of 15-20 micro-inches, integrally bonded to a special Ultra-High Molecular Weight Polyethylene (UHMW-PE). Tests in the U.S. Navy Trident Submarines resulted in extremely low coefficient of friction, less break-in running time, vibration damping, and extremely quiet operation.

DMX Polymer Stave Bearings

As a hybrid polymer alloy material, it is the ultimate bearing material proven to perform outstandingly in the harshest, grittiest, dirtiest working environments. It is perfect for work boats around inland brown waters and as dredger propulsion bearings. It can be used in a 1:1 (length to diameter ratio) or less configuration. DMX was independently tested and showed zero shaft and bearing wear in both clean and gritted water testing.

Shaft Sealing Systems

No one realizes more than Duramax Marine how important a shaft seal system is in keeping a vessel safe and operating at peak performance. Our systems are built for optimum performance, long service at sea, and ease of maintenance.

No one realizes more than Duramax Marine how important a shaft seal system is in keeping a vessel safe and operating at peak performance. Our systems are built for optimum performance, long service at sea, and ease of maintenance.

Many of our Johnson heavy-duty stuffing boxes have been known to last the life of the ship.

It's what you would expect from Duramax Marine - a product you can trust, supported by a staff of sealing experts to solve any problems you might experience.Johnson Heavy-Duty Air-Seal Stuffing Box

Duramax heavy-duty stuffing boxes are used for sealing stern tubes, bulkheads and rudder ports. Robust construction, high quality alloys and precision machining allows them to withstand long service life at sea - many lasting the life of the vessel. First to feature "Air Seal" that allowed maintenance of packing at sea without dry docking.

Duramax Ultra-X

High-performance compression packing, engineered specifically for the marine industry. It outlasts other packing 5-1, with 300% lower friction than flax packing. Never hardens. Stays pliable. Never consumed in use. It virtually eliminates packing failure that can wear your shaft. With Ultra-X the stuffing box functions as a heat sink, lowering the temperature of the shaft even at extremely high shaft speeds.

DryMax Stern Tube Seal System

The DryMax Shaft Seal is a reliable system that uses no grease or oil and is easy to install and maintain. The DryMax Shaft Seal eliminates wear on propulsion shafts caused by traditional radial lip sealing systems. The unique nature of the DryMax design creates a highly effective seal which accommodates shaft movement in both the axial and radial directions.

Mechanical Shaft Seal System

Commercial grade protection for engineered propeller shafts and rudder assemblies. It's a maintenance-free design, manufactured in the U.S.A. Available in shaft sizes from 3/4" to 6-3/4" diameters. Easy to install for O.E.M. or retrofit installations.

Heat Exchange Systems

Duramax Marine has delivered the latest in cooling systems for over 40 years.

Marine professionals rely on our product specialists to recommend the right type of cooling system for your vessel's structure. Whether it's new construction, replacing an old system, or re-powering, one of our heat exchange experts will discuss with you your exact cooling requirements. Then they will engineer a highly efficient, easy-to-install and easy-to-maintain heat exchange the ever-changing power demands of the marine industry.DuraCooler Keel Cooler

Streamlined header design improves the efficiency of the traditional squared-headed keel cooler. Using computer studies and full-scale flow testing, we improved heat transfer by more than 17%. Coolant flow distribution to the outside tubes increased 35%, while heat rejection increased 45%. Its smaller footprint reduces hull space and cooling costs.

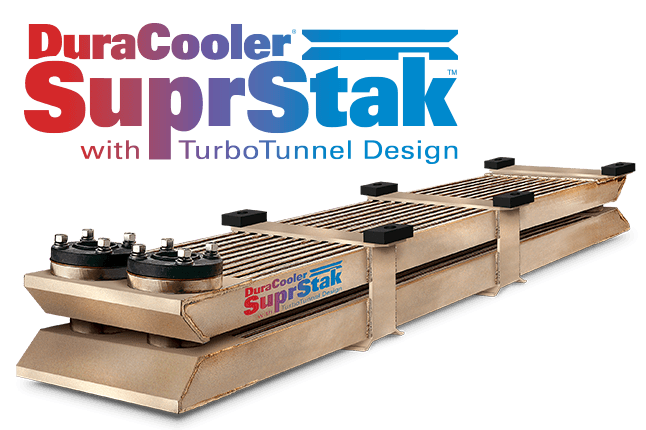

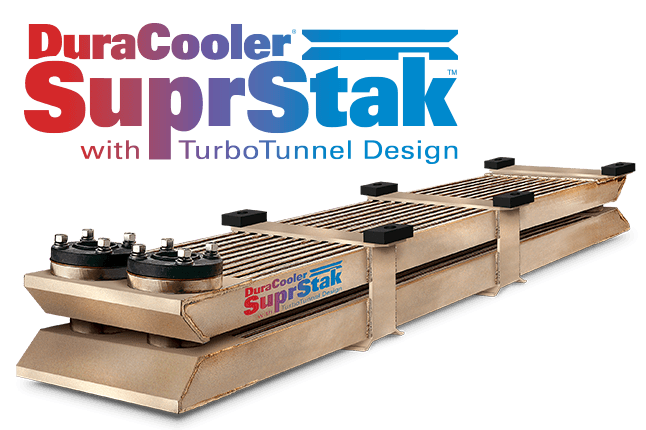

DuraCooler SuprStak Keel Cooler

Revolutionary keel cooler design more than doubles heat transfer in half the hull space. The best answer for the marine industry's ever increasing cooling requirements. It is a double-stacked, completely redesigned DuraCooler engineered to "jet" turbulent seawater in a tunnel-like configuration between its upper and lower tube assemblies.

Demountable Keel Cooler

Duramax 90/10 copper-nickel spiral tubes offer superior heat transfer and design flexibility for cooling main and auxiliary engines on steel-hulled vessels. It's easily expandable to re-power. Modular design allows for multiple cooling circuits. No through-hull fittings or seachest required. Flexible copper-nickel tubes form to hull and are naturally resistant to biological marine fouling.

Duramax Box Coolers

Operates in a seachest, protected against damage from underwater hazards. Engine cooling water is pumped through an aluminum brass (CuZn20Al) tube bundle. Seawater entering the seachest creates a convection current transferring heat into the sea, away from vessel's engine. An anti-fouling system (ICAF) and heat-cured synthetic coated tubes protect unit from galvanic corrosion and biological marine growth.

Impact Protection Systems

With Duramax Marine you will always get the latest technology in impact protection systems available to protect your vessels and structures.

Our experienced, knowledgeable staff can discuss your needs, then recommend the right system for the job. We have a large inventory of profiles and materials in stock, conveniently located in Ohio and Louisiana. Our staff will custom design your system to fit your exact dimensions, then fabricate it to fit accurately and save installation time. Commercial Dock Bumpers, Fenders, and Tow Knees

Manufactured of highest quality EPDM (Ethylene Propylene-Diene-Monomer) rubber. Unaffected by ozone and perform up to 4X longer than inferior rubber compounds when exposed to harsh marine environments. We design, engineer, fabricate and rigorously test our systems to meet or exceed industry tolerance standards. Large selection of sizes, profiles and colors in stock, with shortest lead times of any supplier.

Duramax Linerite Batterboard Systems

Linerite composite batterboard is engineered for the most challenging impact applications. Our unique material absorbs impact energy and provides a nearly indestructible layer of protection. Linerite fuses two integral materials together at the molecular level: 0.12 low coefficient of friction Ultra-High Molecular Weight Polyethylene (UHMW-PE) facing, and a proprietary energy absorbing composite core. Comes in standard black, grey, white, OSHA or any custom matched color.